How AI Predictive Analytics Enhances Supply Chain Efficiency

Enterprise AI Solutions | Innovative AI Applications | AI Automation Services in 2026

AI predictive analytics is transforming how organizations plan, operate, and protect modern supply chains in an environment defined by uncertainty and speed. As global networks become increasingly complex, businesses can no longer rely on static forecasts or manual planning to maintain supply chain efficiency and consistently meet customer expectations.

Today’s supply chains generate massive volumes of data across sales, inventory, logistics, production, and transportation. However, when powered by business intelligence, advanced data analysis techniques, and AI models, this data shifts from an operational burden to a strategic asset. As a result, instead of reacting to delays, shortages, or cost spikes after they occur, organizations can anticipate outcomes and act proactively.

Moreover, AI predictive analytics enables organizations to improve demand forecasting, strengthen inventory optimization, reduce operational risk, and increase OTIF on time in full performance. By combining machine learning algorithms and applications, artificial neural networks, and real-time ecosystem signals, predictive systems continuously learn and adapt to changing conditions.

In this guide, we explain what AI predictive analytics means for supply chains, how it works, where it delivers the highest impact, and how organizations can use it to build resilience, agility, and long-term competitive advantage.

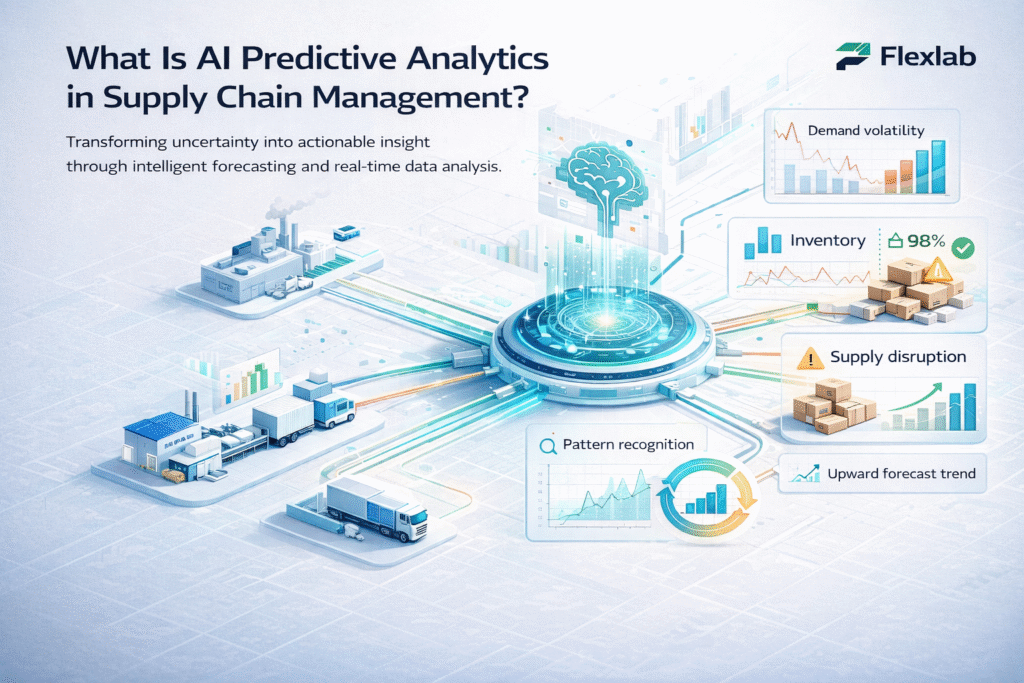

What Is AI Predictive Analytics in Supply Chain Management?

AI predictive analytics in supply chain management refers to the use of intelligent systems and advanced algorithms to analyze historical and real-time data to forecast future outcomes. Rather than relying on assumptions or static reports, organizations use predictive analytics to anticipate demand shifts, supply disruptions, and operational bottlenecks before they affect performance.

By combining data from sales, manufacturing, logistics, and external market signals, predictive systems transform uncertainty into actionable insight. Consequently, businesses move from reactive planning to proactive execution, improving accuracy, efficiency, and decision speed across the entire supply chain.

Business Challenges AI Predictive Analytics Solves

Modern supply chains face persistent challenges, including demand volatility, forecast inaccuracies, excess inventory, stockouts, and poor OTIF performance. In addition, limited visibility into disruptions often forces organizations into costly last-minute decisions.

AI predictive analytics addresses these challenges by providing early visibility into potential risks and opportunities. As a result, organizations can stabilize operations, reduce inefficiencies, and improve customer service while maintaining cost control.

How Predictive Analytics Models Work in Supply Chains

At the core of AI-driven forecasting are predictive analytics models that identify patterns, trends, and anomalies across large datasets. These models evaluate historical demand, seasonality, supplier performance, and transportation data to predict what is likely to happen next.

Unlike traditional forecasting methods, predictive models continuously improve as new data becomes available. Therefore, supply chain leaders can adjust plans in near real time, significantly reducing errors and minimizing costly surprises.

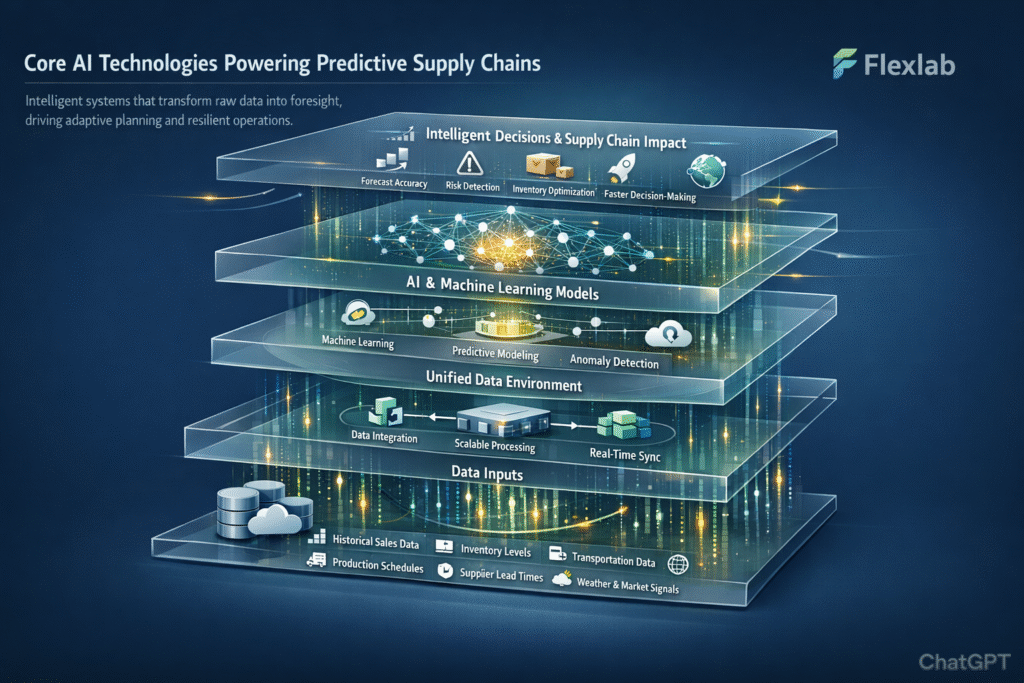

Core AI Technologies Powering Predictive Supply Chains

At the core of modern predictive supply chains are intelligent AI technologies that enable organizations to transform data into foresight. These technologies support advanced pattern recognition, continuous learning, and faster decision-making across complex and fast-moving supply networks.

By combining scalable data processing with adaptive analytical capabilities, organizations can enhance planning accuracy, anticipate disruptions, and support more resilient and responsive supply chain operations.

Data Requirements for AI Predictive Analytics

The effectiveness of AI predictive analytics depends heavily on data quality and consistency. While organizations do not need perfect data, they do need reliable inputs across the supply chain.

Key data sources typically include historical sales data, inventory levels, supplier lead times, production schedules, transportation data, and external signals such as weather patterns and market trends. When integrated into a unified environment, these datasets enable more accurate and actionable predictions.

Core AI Technologies Explained

AI predictive analytics is powered by machine learning algorithms and applications that allow systems to learn from data without explicit programming. Over time, these models adapt to changing conditions, improving forecast accuracy and responsiveness.

More advanced use cases rely on artificial neural networks and deep learning techniques to model complex, non-linear relationships. This capability is especially valuable for demand sensing, risk detection, and managing highly dynamic global supply chain environments.

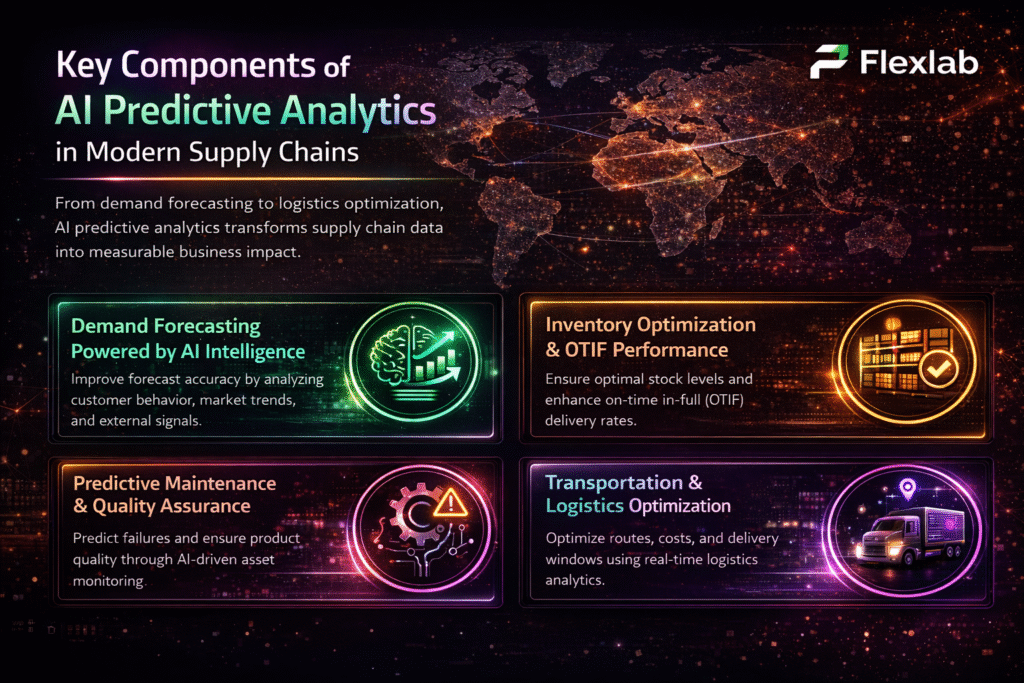

Key Components of AI Predictive Analytics in Modern Supply Chains

AI predictive analytics delivers value through interconnected components that transform raw data into forecasts, recommendations, and automated actions. When implemented correctly, these components improve both operational performance and strategic decision-making.

1. Demand Forecasting Powered by AI Intelligence

AI-driven demand forecasting evaluates customer behavior, market trends, promotions, and external signals, rather than relying solely on historical averages. As a result, organizations achieve higher forecast precision while reducing overproduction and stockouts.

Real-world impact: Retailers using AI-based forecasting report forecast accuracy improvements of 20–30%, according to industry studies.

2. Inventory Optimization and OTIF Performance

Predictive inventory optimization ensures the right products are available at the right time and location, without tying up excess working capital. Consequently, improved inventory decisions directly enhance OTIF (on time in full) performance, strengthening customer trust and operational reliability.

3. Predictive Maintenance and Quality Assurance

Predictive maintenance uses AI to monitor asset health, sensor data, and performance trends to anticipate failures before they occur. As a result, organizations reduce downtime, prevent quality issues, and maintain consistent production schedules.

4. Transportation and Logistics Optimization

AI enhances logistics planning by analyzing routes, carrier performance, fuel costs, and delivery constraints in real time. When integrated with transportation management systems, predictive analytics enables dynamic routing, smarter carrier selection, and faster exception handling.

5. KPIs Impacted by AI Predictive Analytics

AI predictive analytics directly improves key performance indicators, including forecast accuracy, inventory turnover, service levels, OTIF performance, logistics cost per unit, and working capital efficiency. Together, these improvements deliver measurable business impact.

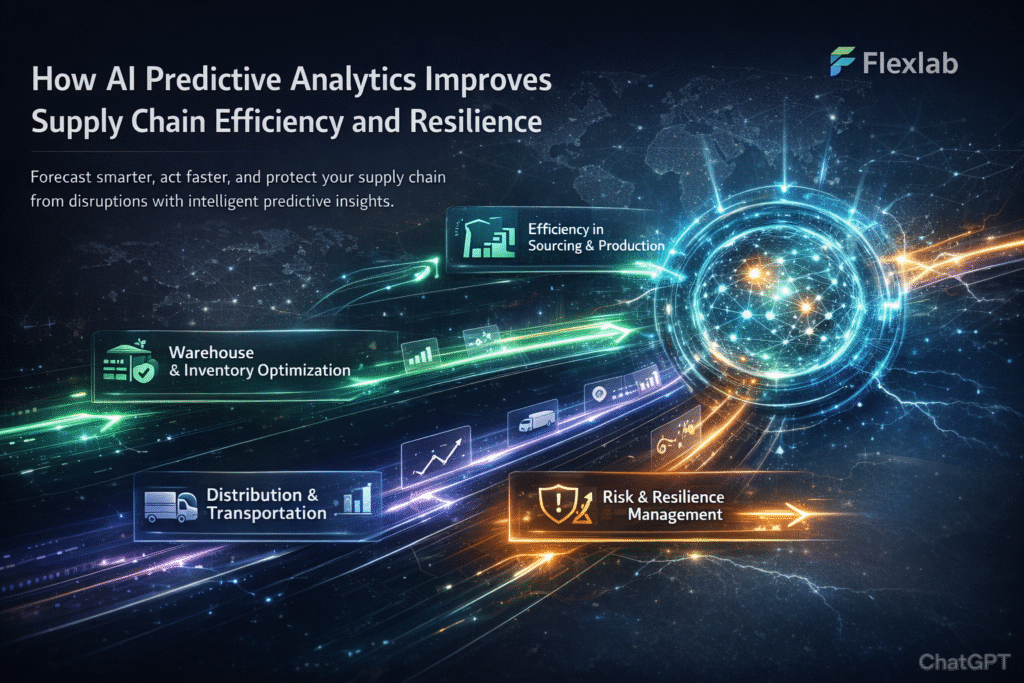

How AI Predictive Analytics Improves Supply Chain Efficiency and Resilience

AI predictive analytics reshapes supply chains by enabling faster responses, smarter planning, and stronger risk preparedness. Additionally, by forecasting outcomes, organizations improve operational continuity while adapting to changing market conditions.

-

Driving End-to-End Supply Chain Efficiency

AI-powered insights help eliminate inefficiencies across sourcing, production, warehousing, and distribution. Therefore, organizations achieve faster cycle times, lower operating costs, and better demand–supply alignment.

-

Strengthening Supply Chain Resilience Against Disruptions

Predictive analytics enhances supply chain resilience by modeling risk scenarios and estimating their potential impact. Consequently, teams can reroute shipments, shift sourcing strategies, or adjust inventory buffers before disruptions affect customers.

-

Smarter Supply Chain Strategies Through Predictive Insight

Predictive insights support data-driven supply chain strategies related to network design, capacity planning, and supplier diversification. As a result, strategies remain aligned with business goals and customer expectations.

Implementing AI Predictive Analytics Successfully

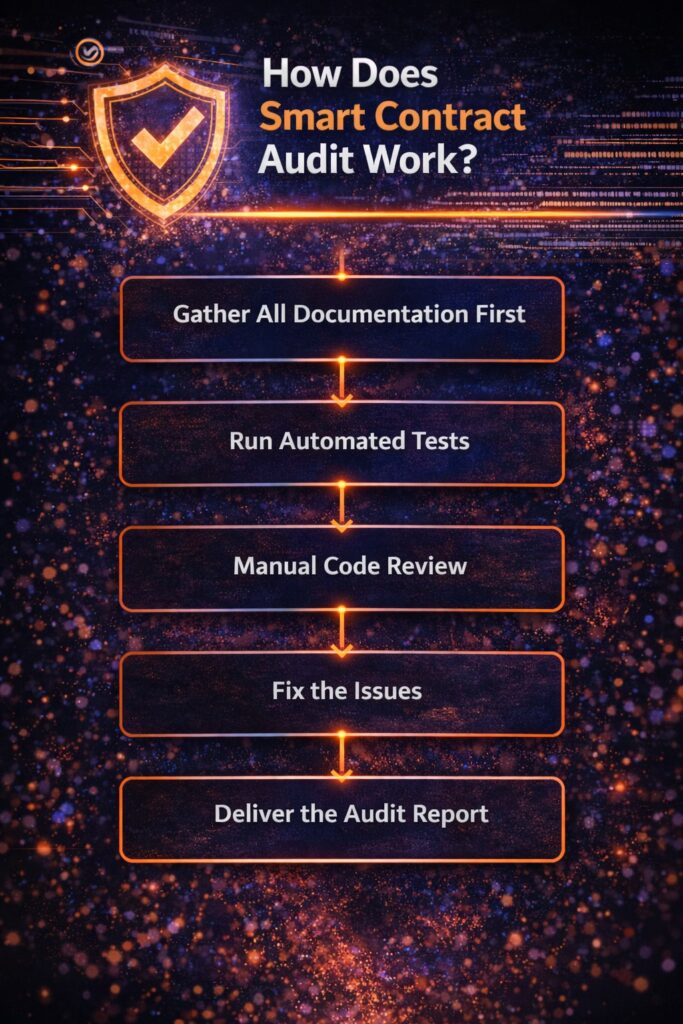

Successfully implementing AI in supply chains requires a structured approach that balances technology, data, and human expertise. Organizations must begin with focused pilot projects, ensuring that data quality, integration with existing systems, and user adoption are prioritized from the outset.

By carefully planning each stage, organizations can leverage AI predictive analytics to generate actionable insights while minimizing risks. Proper governance, continuous monitoring, and cross-functional collaboration are critical to ensure that predictive models remain accurate, relevant, and aligned with business goals.

Core Components of AI Predictive Analytics in Supply Chain

| Component | Primary Function | Business Impact |

| Demand Forecasting | Predict future customer demand | Higher accuracy, reduced stockouts |

| Inventory Optimization | Balance stock levels and service | Lower holding costs, better OTIF |

| Predictive Maintenance | Anticipate equipment failures | Less downtime, higher output |

| Transportation Optimization | Improve routing and delivery | Lower logistics costs, faster delivery |

Implementation Considerations and Best Practices

Successful adoption requires more than advanced technology. Organizations should start with focused pilot use cases, prioritize data quality, integrate with ERP enterprise resource planning systems, and maintain human oversight during early automation stages.

Common Pitfalls to Avoid

Common pitfalls include over-automation too early, weak data governance, unrealistic ROI expectations, and treating AI as a one-time deployment. Organizations that view AI as a continuous improvement capability achieve more sustainable results.

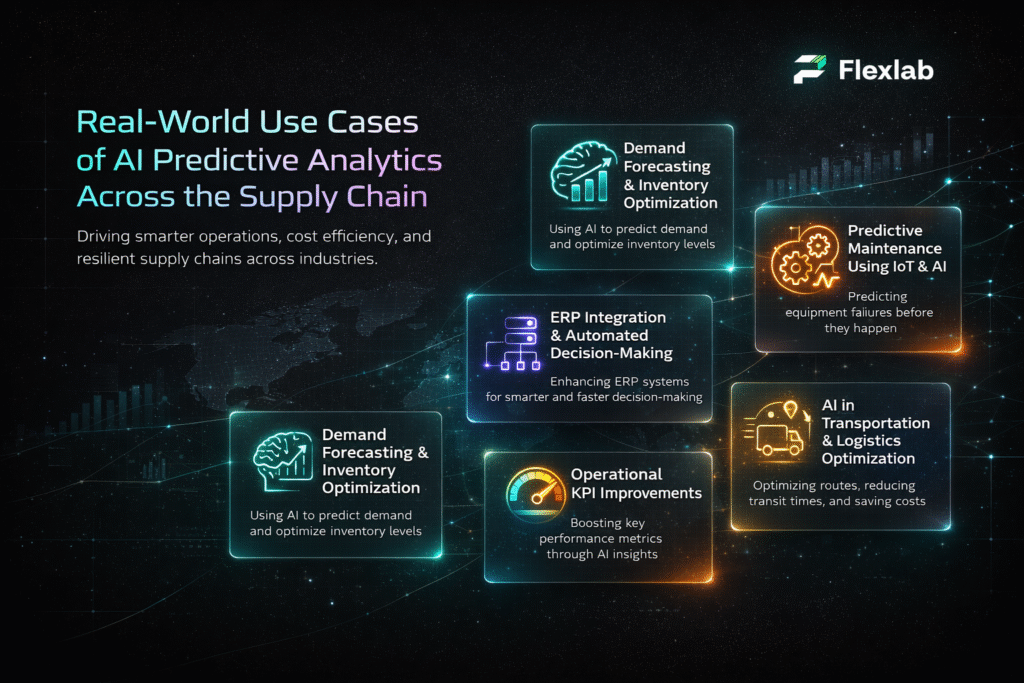

Real-World Use Cases of AI Predictive Analytics Across the Supply Chain

AI predictive analytics delivers measurable value across industries by enabling proactive, data-driven execution. Across sectors such as retail, manufacturing, logistics, and pharmaceuticals, organizations are increasingly leveraging predictive intelligence to optimize operations, reduce costs, and improve service levels.

Demand Forecasting and Inventory Optimization at Scale

Organizations using predictive analytics report inventory holding cost reductions of up to 20% while simultaneously improving service levels. Consequently, smarter stock positioning enhances cash flow, reduces waste, and ensures customers receive products on time. Moreover, predictive forecasting allows companies to anticipate seasonal spikes and market shifts, which can improve forecast accuracy by 15–30% according to industry benchmarks.

Predictive Maintenance Using IoT and AI Systems

By combining IoT sensors with AI models, predictive maintenance identifies early warning signs of equipment failure. As a result, unplanned downtime can be reduced by up to 30%, extending asset lifespan and preventing costly operational disruptions. Additionally, organizations benefit from optimized maintenance schedules, reduced repair costs, and improved production reliability. This capability is particularly valuable for manufacturers and logistics providers managing high-value machinery or fleets.

ERP Integration and Automated Decision-Making

Modern ERP platforms increasingly embed predictive analytics to enable automated decision-making. With AI copilots, planners receive contextual recommendations rather than static reports, accelerating decision cycles and minimizing human error. Consequently, companies achieve faster response times, higher operational efficiency, and improved OTIF (on-time, in-full) performance. Furthermore, integration with ERP systems allows predictive insights to flow directly into procurement, production, and distribution planning, enhancing overall supply chain agility.

AI in Transportation and Logistics Optimization

AI predictive analytics is transforming transportation and logistics by enabling smarter routing, predictive maintenance, and real-time decision-making across complex supply networks. By leveraging these technologies, organizations can proactively manage shipments, avoid bottlenecks, and reduce costs, even in volatile conditions.

According to Statista, companies adopting AI in logistics report transportation cost reductions of up to 15% while improving delivery speed by 12–18%. Moreover, AI-driven routing optimizes carrier selection, fleet utilization, and delivery scheduling, which directly enhances OTIF (on-time, in-full) performance and customer satisfaction.

In addition, integrating IoT technology with predictive analytics allows organizations to monitor vehicles and warehouse assets in real time. Consequently, predictive maintenance reduces unplanned downtime by up to 30%, extends asset lifespan, and prevents costly delays. Furthermore, AI systems can dynamically adjust routes during peak demand or unexpected disruptions, ensuring shipments are delivered efficiently while minimizing fuel consumption and operational risk.

By combining AI technologies with transportation management systems (TMS), companies achieve higher operational reliability, improved cost efficiency, and increased overall supply chain agility. For example, global logistics providers using AI-driven networks report up to 20% faster turnaround times across multi-node supply chains. Meanwhile, predictive insights help planners make informed decisions, reducing human error and enabling automated rerouting when conditions change.

Overall, AI in transportation and logistics not only lowers costs and improves speed but also strengthens resilience, responsiveness, and operational transparency across the supply chain.

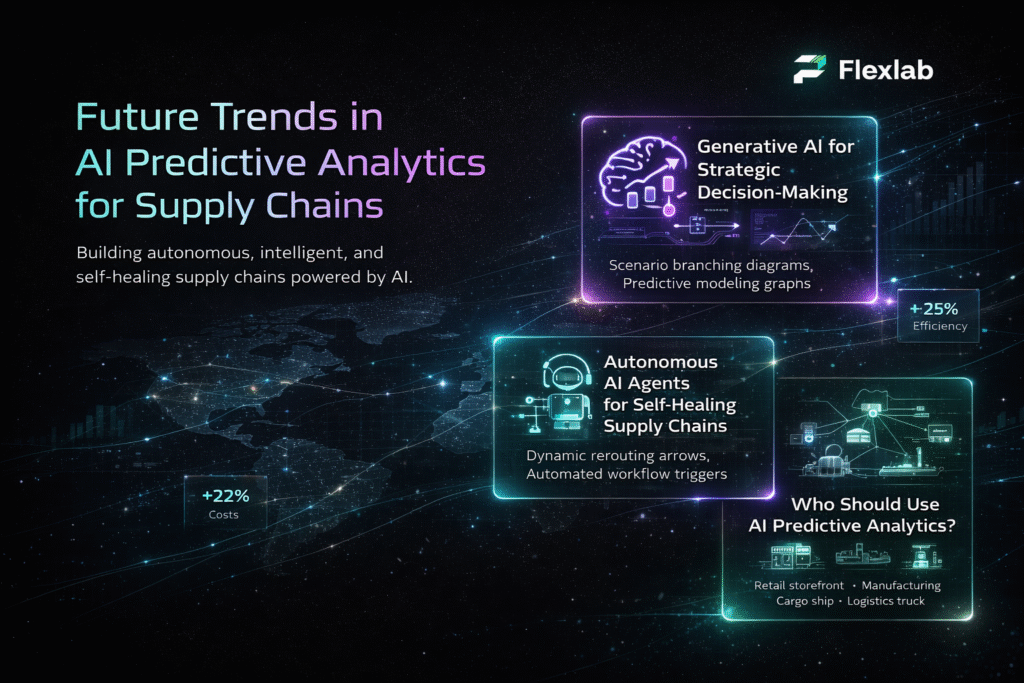

Future Trends in AI Predictive Analytics for Supply Chains

The future of supply chains is becoming increasingly autonomous and intelligent, driven by rapid advancements in AI predictive analytics. According to Gartner (2026), over 65% of leading organizations are expected to adopt autonomous AI agents and predictive analytics at scale, improving operational efficiency by up to 25%.

Generative AI for Strategic Decision-Making

Generative AI is reshaping strategic planning by enabling scenario simulation, optimized decision-making, and advanced forecasting. Consequently, supply chain leaders can model multiple sourcing strategies, evaluate demand fluctuations, and design resilient networks before disruptions occur. Real-world applications show that companies using generative AI for scenario planning can reduce supply chain costs by up to 12% while maintaining high service levels.

Autonomous AI Agents for Self-Healing Supply Chains

Autonomous AI agents detect disruptions, reroute shipments, and trigger replenishment workflows without human intervention. As a result, organizations experience faster response times, reduced emergency shipping costs, and improved OTIF performance. Moreover, by continuously monitoring real-time signals from suppliers, transportation networks, and warehouses, these agents enhance supply chain resilience and support proactive risk mitigation.

Who Should Use AI Predictive Analytics?

AI predictive analytics is most effective for organizations operating complex, multi-node supply chains with high demand variability. Industries that benefit significantly include retail, manufacturing, logistics, pharmaceuticals, consumer packaged goods (CPG), and global distribution networks.

Moreover, enterprises with multiple warehouses, regional distribution centers, or international suppliers can leverage predictive analytics to optimize inventory, reduce costs, and enhance customer satisfaction. Consequently, organizations adopting these technologies gain a competitive edge by making faster, smarter, and more data-driven decisions.

Flexlab Leading the Future of Predictive Supply Chain Analytics

If you’re ready to move beyond reactive planning and fully unlock the value of AI predictive analytics in your supply chain, now is the time to act with confidence. At Flexlab, we design and deliver intelligent, data-driven solutions that elevate forecasting accuracy, reduce operational risk, and strengthen end-to-end supply chain resilience.

Whether you are adopting AI for the first time or scaling existing predictive capabilities, our team works alongside you to build solutions that drive measurable performance gains, faster decision-making, and long-term competitive advantage.

Ready to Move from Reactive to Predictive Supply Chain Performance

📞 Book a FREE Consultation Call: +1 (416) 477-9616

📧 Email Us: info@flexlab.io

To understand how we deliver real impact, explore our services, and see how we enable AI-driven transformation across industries. You can also review our portfolio to discover real-world solutions we’ve implemented. If you’re ready to start the conversation, connect with us through our contact us page.

For ongoing insights on AI, automation, and advanced analytics, visit our website, explore our latest perspectives on the blog, or follow us on LinkedIn to stay ahead of emerging trends, use cases, and expert insights.

- Is AI in Marketing Worth the Investment for Small Businesses?

- How Flexlab Helps Toronto Businesses Scale Faster With AI Automation

- How Does AI in Transportation Support Autonomous Vehicles? A Comprehensive Guide

Conclusion: AI Predictive Analytics Driving Future-Ready Supply Chains

AI predictive analytics transforms supply chains from reactive to proactive by improving forecast accuracy, inventory management, OTIF performance, and operational efficiency. By leveraging machine learning, deep learning, and AI copilots, organizations gain actionable insights that drive resilience and competitive advantage. Organizations that embrace AI predictive analytics today build supply chains that are efficient, adaptive, resilient, and ready for tomorrow’s challenges.

FAQ’s

1. How long does it take to implement AI predictive analytics in a supply chain?

Implementation time varies depending on the complexity of the supply chain and data quality. For most mid-to-large organizations, initial pilots can take 3–6 months, while full-scale deployment may take 12–18 months. Starting with a small, focused project often helps teams gain quick insights and build confidence before scaling. Additionally, continuous monitoring and model adjustments are essential for long-term success, as supply chain conditions evolve over time.

2. Can small businesses benefit from AI predictive analytics in supply chains?

Absolutely! While AI is often associated with large enterprises, small businesses can leverage cloud-based predictive analytics tools. By analyzing sales, inventory, and supplier data, even smaller operations can optimize stock, improve delivery reliability, and anticipate disruptions without huge infrastructure investments. Over time, this can create significant cost savings and give smaller companies a competitive edge in their markets.

3. What types of supply chain decisions can AI predictive analytics improve?

AI predictive analytics supports decisions across demand planning, inventory management, transportation, and risk mitigation. It helps organizations decide when to replenish stock, how to route shipments, and how to prepare for supplier delays. Essentially, it turns data into actionable insights that reduce cost and improve service levels. Moreover, predictive analytics can guide strategic decisions like supplier selection and capacity planning to strengthen overall supply chain resilience.